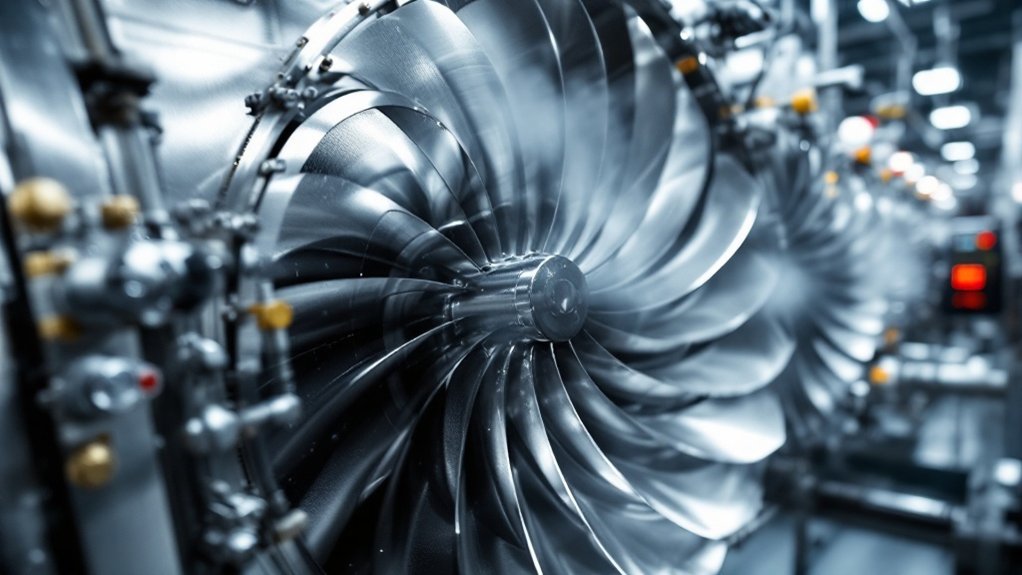

Steam turbine efficiency hinges on several key factors. Modern design uses computer modeling to optimize blade shapes and steam paths. Proper operating conditions, including temperature and pressure control, are essential. Regular maintenance keeps components working well. Advanced control systems help manage steam flow precisely. Heat recovery systems capture waste energy. Efficiency also improves with cogeneration and retrofitting older turbines. These practices can boost performance by significant percentages in most installations.

As energy costs continue to rise, engineers are focusing on ways to improve steam turbine efficiency across power plants worldwide. Modern design techniques have revolutionized how these important power generators work. Engineers now use computer modeling to improve blade shapes and create better steam paths. These changes reduce energy losses and help turbines convert more steam energy into electricity.

Operating conditions play a major role in efficiency. Higher steam temperatures generally produce better results, but the pressure must be just right. Plants must also control steam quality and exhaust pressure. When turbines run at partial loads, special techniques help maintain good performance levels.

Perfect operating conditions are essential—temperature, pressure, steam quality, and special load management all impact turbine efficiency.

Regular maintenance keeps turbines running efficiently. Cleaning blades, replacing worn parts, and keeping everything properly aligned prevents energy waste. Good lubrication reduces friction, and modern monitoring systems can spot problems before they cause breakdowns or efficiency drops.

Today’s control systems make a big difference in turbine performance. Advanced governors manage steam flow precisely, while integrated controls coordinate the entire plant. Real-time monitoring lets operators make quick adjustments when needed. Some plants now use digital twin technology—virtual copies of their turbines—to find the best operating settings.

Heat recovery systems capture energy that would otherwise go to waste. Feedwater heating, regenerative cycles, and steam reheating all boost efficiency. Many plants use cogeneration, which captures extra heat for industrial processes or building heating. Achieving optimal results requires maintaining a high vapor fraction with low moisture content to maximize heat transfer efficiency throughout the system. Accurate efficiency calculations require enthalpy drop measurements taken at both pre-turbine and post-turbine positions to determine actual steam energy conversion.

Older turbines don’t need to be replaced entirely. Retrofitting with modern components, better materials, and updated controls can greatly improve their efficiency. Newer technologies like.3D-printed parts offer new possibilities for complex components.

Environmental factors also affect efficiency. Water treatment systems and condensate polishing help maintain steam quality. Optimized cooling systems improve condenser performance. As climate concerns grow, designers must consider how environmental conditions will affect turbine operation throughout its service life.

Frequently Asked Questions

How Often Should Steam Turbines Undergo Preventive Maintenance?

Steam turbines typically require annual inspections, with major overhauls every 5-7 years.

Daily and weekly monitoring of key parameters is standard practice.

Well-maintained units can extend intervals to 10-12 years using condition-based maintenance.

Maintenance frequency varies based on operating conditions, starts/stops, steam quality, and equipment age.

Regular maintenance extends turbine lifespan by 20-30 years and improves efficiency by 2-5%.

What Environmental Impacts Are Associated With Steam Turbine Operations?

Steam turbines impact the environment in several ways.

They produce air emissions including CO2, NOx, and SOx when burning fossil fuels. They require large amounts of water for cooling, which can affect local water supplies. Heated discharge water can harm aquatic life.

The plants also take up physical space, potentially disrupting habitats. Additional impacts come from fuel extraction and transportation needed to power the turbines.

How Do Digital Twin Technologies Enhance Turbine Monitoring?

Digital twin technologies create virtual models of steam turbines that work like their real counterparts.

These systems collect data from sensors that track temperature, pressure, and vibration. They can predict when parts might fail, reducing unexpected shutdowns by up to 40%.

They also help optimize operations, improving efficiency by 1-3%. Operators can test new settings safely without risking actual equipment.

Maintenance costs drop by 10-40% with this technology.

What Safety Protocols Are Essential for Steam Turbine Operators?

Steam turbine operators rely on multiple safety protocols to prevent accidents.

PPE including hard hats, safety glasses, and heat-resistant gloves is mandatory. Strict lockout/tagout procedures guarantee equipment is fully powered down during maintenance.

Emergency procedures cover fires, explosions, and steam leaks with clear exit routes. Monitoring systems continuously track temperature and pressure, triggering alarms for abnormal conditions.

Regular safety drills and equipment checks are standard practice.

How Do Cogeneration Systems Affect Overall Plant Efficiency?

Cogeneration systems boost plant efficiency by capturing waste heat to produce both electricity and useful thermal energy.

These systems achieve 65-90% total efficiency compared to just 50-55% with separate heat and power generation.

Plants using cogeneration reduce fuel consumption by 10-40%, lower energy costs by 15-40%, and cut CO2 emissions by 30-50%.

They also avoid 5-10% transmission losses associated with grid electricity.