Hydrogen fuel cells are manufactured through a multi-step process. Workers create the core component—a membrane electrode assembly (MEA)—by applying catalyst inks to membranes or gas diffusion layers. They sandwich these between bipolar plates that manage gas flow. The complete stack combines alternating MEAs and plates with supporting components. Quality control includes voltage testing and leak checks. Advanced techniques like roll-to-roll processing are transforming production methods.

Hydrogen fuel cells are powering a clean energy revolution across the globe. These devices convert hydrogen and oxygen into electricity, with water as the only byproduct. The manufacturing process involves several precise steps to create these clean energy generators.

Every fuel cell starts with a core structure of three main parts: an anode, a cathode, and an electrolyte membrane between them. Manufacturers apply special catalyst layers, usually containing platinum, to the electrodes. These catalysts speed up the chemical reactions that produce electricity.

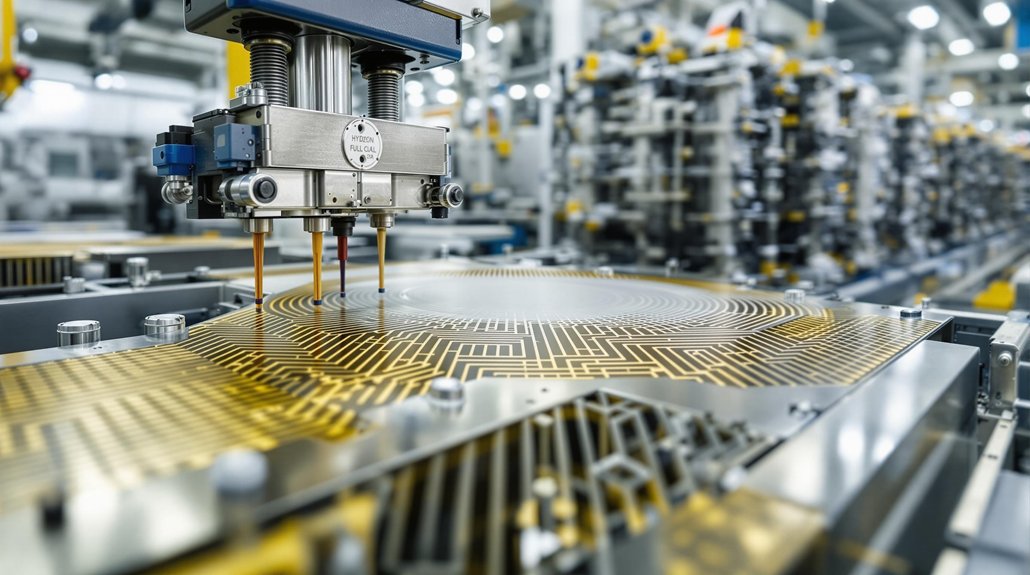

The production of the Membrane Electrode Assembly (MEA) is a critical step. Workers mix catalyst powder with a solution called ionomer to create a catalyst ink. They apply this ink to gas diffusion layers or directly to the membrane through spraying or printing methods. The components are then bonded together using heat and pressure in a process called hot pressing.

Creating the MEA requires precision chemistry—catalyst inks applied meticulously, then transformed through heat and pressure into a unified powerhouse.

Bipolar plates play a key role in fuel cell function. For cars, manufacturers often use stamped metal plates, while stationary power systems typically use molded graphite composite plates. These plates need precise channels for gas flow, created through machining or molding processes. Protective coatings help prevent corrosion.

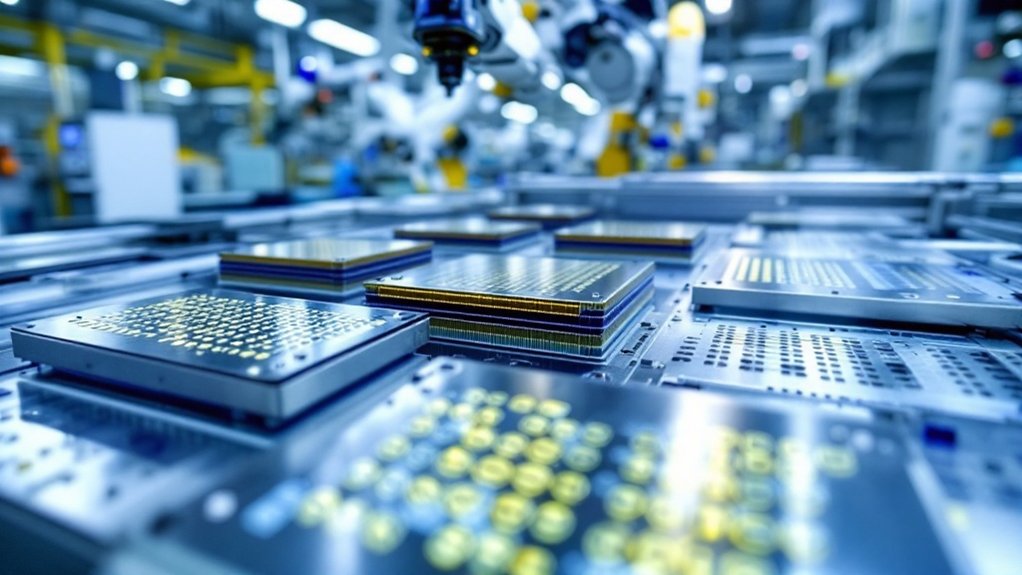

During stack assembly, workers arrange MEAs and bipolar plates in alternating layers. They apply uniform pressure to seal all components together. End plates, current collectors, and manifolds complete the assembly. Many companies now use automated assembly lines for high-volume production.

The fuel cell system also needs “balance of plant” components. These include fuel processors, air compressors, cooling systems, and power conditioners that convert the direct current to usable alternating current. The completed cells operate with no moving parts and generate electricity silently through electrochemical reactions rather than combustion.

Quality control is essential throughout manufacturing. Technicians test each cell for voltage, check for leaks, and measure overall performance. Companies use automated vision systems to spot tiny defects that human eyes might miss. Raw materials undergo rigorous quality control to ensure they meet the exact specifications required for effective fuel cell performance.

Manufacturers continue to innovate by reducing expensive platinum use, developing roll-to-roll processing methods, and exploring 3D printing for complex components. These advances are making fuel cells more affordable and efficient.

Frequently Asked Questions

What Is the Average Lifespan of a Hydrogen Fuel Cell?

Hydrogen fuel cells don’t last the same amount of time in all applications. For cars, they typically run for 5,000-10,000 hours or about 5-10 years.

Heavy-duty vehicles like buses see 20,000-30,000 hours.

Stationary systems last longest at 40,000+ hours.

Lifespan depends on operating conditions, maintenance, and how often the system starts and stops.

Manufacturers are working to extend these lifespans through improved materials and designs.

How Much Does a Typical Hydrogen Fuel Cell Cost?

Hydrogen fuel cell costs vary widely based on production volume. High-volume production costs range from $50-$100 per kilowatt, while low-volume production runs $200-$1000 per kilowatt.

Complete automotive fuel cell systems cost $30,000-$50,000 per vehicle. Stationary systems for buildings run $3000-$6000 per kilowatt.

Costs have dropped 60% since 2006, with another 75% reduction expected by 2030. Government incentives continue supporting price decreases.

Can Hydrogen Fuel Cells Be Recycled?

Yes, hydrogen fuel cells can be recycled.

Various methods exist to recover valuable materials. Companies can extract platinum and other precious metals at 64-99% yield rates.

The membrane materials like Nafion are also recyclable. Carbon fiber, graphite, and metals from components can be reused.

This recycling process reduces material costs by 19-55% and cuts greenhouse gas emissions by 16-21%.

Do Hydrogen Fuel Cells Work in Extreme Temperatures?

Hydrogen fuel cells do work in extreme temperatures, showing good performance in both cold and hot conditions. They can function down to -30°C, outperforming battery-electric vehicles in extreme cold.

While cold weather can reduce range by about 23%, proper temperature management helps maintain efficiency.

In hot conditions, some fuel cells operate above 100°C, with higher temperatures actually improving reaction efficiency when managed correctly.

How Do Hydrogen Fuel Cells Compare to Lithium-Ion Batteries?

Hydrogen fuel cells and lithium-ion batteries offer different advantages in powering vehicles.

Fuel cells provide longer range (300-400 miles) and faster refueling (3-5 minutes), while producing only water as emission. They also perform better in cold weather.

However, lithium-ion batteries cost less upfront and have better infrastructure support with more charging stations.

Fuel cells maintain performance longer, but hydrogen production still largely relies on fossil fuels.