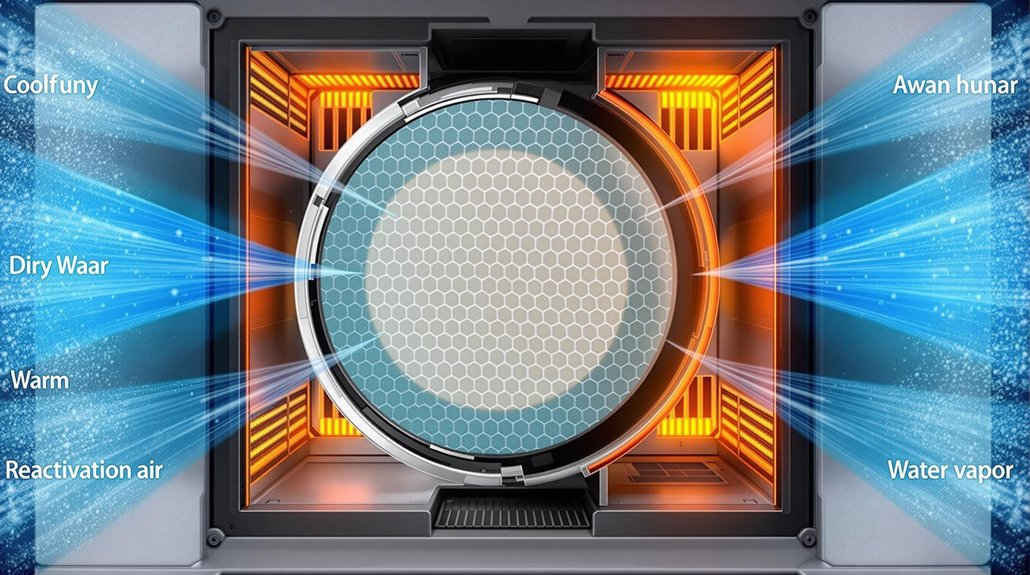

Desiccant dehumidifiers remove moisture using a rotating wheel coated with materials like silica gel or zeolites. As humid air passes through the wheel, these materials attract and trap water molecules through chemical absorption. The wheel slowly turns, and a separate heated airflow regenerates the desiccant by releasing the collected moisture outside. Unlike refrigerant models, they don’t create condensation and work well in cold temperatures. The technology offers unique advantages in specific environments.

While most people are familiar with standard refrigerant-based dehumidifiers, desiccant dehumidifiers offer a different approach to removing moisture from the air. These devices use special materials called desiccants that naturally attract and hold water molecules. The process doesn’t require cooling the air, making them effective even in cold conditions where traditional dehumidifiers struggle.

Desiccant dehumidifiers revolutionize moisture control by using materials that naturally trap water molecules without cooling requirements, excelling where traditional units fail.

At the heart of a desiccant dehumidifier is a wheel or rotor coated with materials like silica gel or zeolite. This wheel rotates slowly at about 8-12 revolutions per hour. As humid air passes through one section of the wheel, the desiccant material pulls moisture from the air. The dried air then returns to the room.

The wheel continues rotating into a separate section where warm air flows in the opposite direction. This warm air, often called reactivation air, heats the desiccant material. The heat causes the trapped moisture to release from the desiccant and exit the machine. This continuous cycle allows the dehumidifier to work non-stop.

Different types of desiccant materials serve various purposes. Silica gel is most common due to its high absorption capacity. Zeolites work well for extremely dry conditions. Other options include activated alumina, which resists contamination, and molecular sieves for specific applications.

These dehumidifiers excel in many situations where traditional units fail. They can operate in very cold environments, down to -4°F, without freezing up. They don’t produce condensate that needs draining. They’re also capable of achieving very low humidity levels, below 35% relative humidity. These systems are designed with few moving parts, making them both reliable and cost-effective to maintain.

Industries rely on desiccant dehumidifiers for sensitive applications. Pharmaceutical companies use them during drug production. Food processors employ them for packaging and storage. Electronics manufacturers protect delicate components with them. Museums and archives preserve valuable artifacts using desiccant technology. Some advanced models with high-quality European components offer superior reliability and performance in line with EU standards.

Recent innovations include hybrid systems that combine desiccant and refrigerant technologies. Manufacturers now incorporate smart sensors and remote monitoring capabilities. Some newer models use renewable energy for the regeneration heating process, improving energy efficiency.

Frequently Asked Questions

How Long Do Desiccant Wheels Typically Last Before Needing Replacement?

Desiccant wheels typically last 8-15 years before replacement is needed. In ideal conditions, they can function for up to 20-25 years.

Their lifespan depends on several factors: operating temperatures, contamination levels, mechanical damage, usage intensity, and environmental conditions.

Signs that a wheel needs replacement include discoloration, reduced performance, increased pressure drop, material brittleness, and visible cracks.

Regular maintenance like filter changes and annual inspections extends wheel life.

Can Desiccant Dehumidifiers Operate Effectively in Freezing Temperatures?

Yes, desiccant dehumidifiers operate effectively in freezing temperatures as low as -4°F (-20°C).

Unlike refrigerant models that struggle below 60°F, desiccant units don’t have coil freezing issues. They use chemical adsorption with a rotating desiccant wheel instead of condensation.

This makes them ideal for unheated spaces like garages, basements, cold storage facilities, ice rinks, and winter construction sites. They even produce warm air as a beneficial byproduct.

What Maintenance Is Required for a Desiccant Dehumidifier?

Desiccant dehumidifiers need regular maintenance to perform well.

Filters should be cleaned every 2-4 weeks using a vacuum or lukewarm water. The desiccant wheel requires annual inspection for dirt and damage.

Maintenance also includes checking airflow systems, cleaning intake grilles, and inspecting fan blades.

General upkeep involves wiping the exterior, checking the condensate drain, and ensuring electrical connections are tight.

More frequent cleaning is needed in dusty environments.

Are Desiccant Dehumidifiers Quieter Than Compressor-Based Models?

Yes, desiccant dehumidifiers are generally quieter than compressor-based models.

They typically operate at 35-45 decibels compared to 45-55 decibels for compressor units.

The absence of a compressor means fewer moving parts and less mechanical noise.

Consumer tests confirm desiccant models average 5-10 decibels quieter.

The fan noise from desiccant units is usually less disruptive than the distinctive buzz from compressor models.

How Much Electricity Do Desiccant Dehumidifiers Consume Compared to Refrigerant Types?

Desiccant dehumidifiers typically consume more electricity than refrigerant models. They use between 240-480 watts compared to refrigerant types that use 210-700 watts.

While desiccant units are less energy-efficient overall, they perform better in cold environments. Refrigerant models can save up to 50% more electricity in warm conditions.

The efficiency gap narrows in low temperatures, where desiccant models become more practical.