Ethylene production primarily occurs through steam cracking, where hydrocarbons are heated with steam at 750-950°C. This process breaks down large molecules into smaller ones with unsaturated bonds. Most European and Asian producers use naphtha as feedstock, while Middle Eastern facilities rely on natural gas components. The process involves three main stages: cracking and quenching, compression and drying, and separation. Further details reveal how this critical industrial process impacts global manufacturing.

Most of the ethylene used worldwide is produced through a process called steam cracking. This chemical process is the primary method for making ethylene and involves heating hydrocarbons with steam at very high temperatures between 750-950°C. The extreme heat breaks down large hydrocarbon molecules into smaller ones and creates unsaturated bonds in the hydrocarbon chains.

The choice of raw materials, or feedstocks, varies by region. European and Asian producers typically use naphtha, while facilities in the Middle East rely on natural gas components like ethane, propane, and butane. This choice depends largely on what’s available locally and at what cost. Some modern plants are designed to handle different feedstocks, giving operators flexibility.

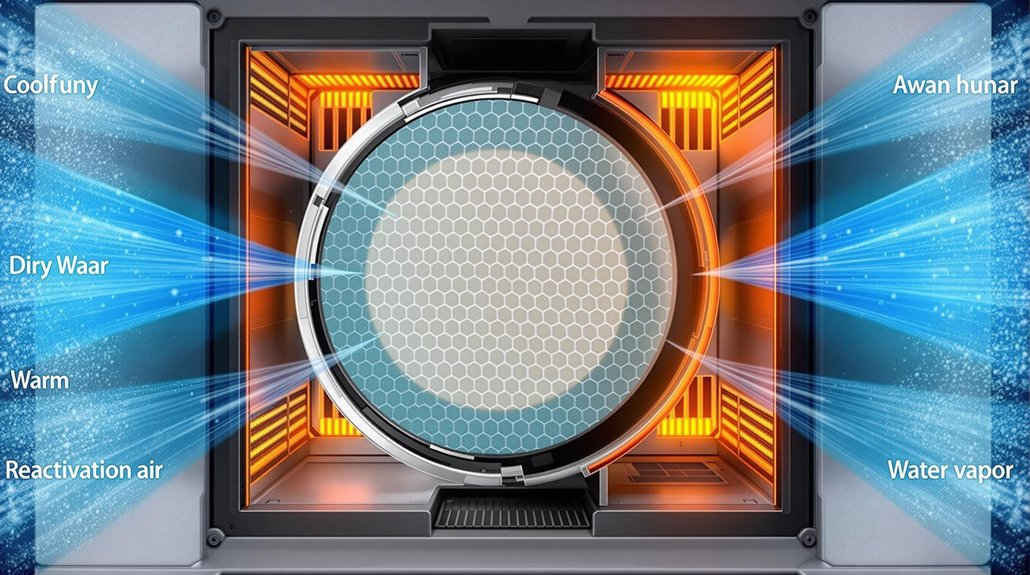

Steam cracking happens in three main stages. First is the cracking and quenching stage, followed by compression and drying, and finally separation. Each stage plays a crucial role in making high-quality ethylene efficiently.

The efficient production of high-quality ethylene relies on three critical stages: cracking and quenching, compression and drying, and separation.

At the heart of production is the cracking furnace. Here, the residence time must be very short to get the best yields. Careful temperature control determines which products are made. After cracking, the gas mixture is quickly cooled or “quenched” to stop unwanted reactions. Water-based quenching systems are essential to prevent further reactions and formation of undesirable byproducts.

The separation process uses extremely cold temperatures to separate the different gases. A series of distillation columns called demethanizer, deethanizer, and depropanizer separate ethylene from other products. This process creates polymer-grade ethylene that’s pure enough for making plastics.

Steam cracking uses a lot of energy and produces carbon dioxide. Engineers constantly work to improve energy efficiency and reduce emissions. The industry has a global capacity exceeding 150 million tons per year, with new plants costing billions of dollars to build.

The economics of ethylene production depend heavily on feedstock prices and the value of co-products made during the process. Market demand for plastics and other ethylene-based products drives decisions to build new production capacity. Research into biological methods using plants and microbes to produce ethylene from 2-oxoglutarate could potentially reduce the petroleum industry’s dominance in ethylene production.

Frequently Asked Questions

What Is the Environmental Impact of Ethylene Production?

Ethylene production has several environmental drawbacks.

It’s a major source of air pollution, releasing VOCs that form smog and ground-level ozone.

The manufacturing process contaminates water and soil through wastewater and potential spills.

It’s extremely energy-intensive, contributing about 1.5% of global industrial CO2 emissions.

Plants and nearby communities face health risks from toxic emissions, and the process damages local ecosystems and vegetation even at low concentrations.

How Much Does It Cost to Build an Ethylene Plant?

Building a new ethylene plant costs between $1.1-1.5 billion for a facility producing one million tons annually.

Construction expenses range from $600-1,300 per ton of capacity.

Recent projects have been even costlier, with Shell’s Pennsylvania plant costing $6 billion for 1.5 million tons of yearly capacity.

Equipment makes up 50-60% of total costs, while construction and labor account for 20-30%.

What Safety Concerns Exist in Ethylene Manufacturing Facilities?

Ethylene manufacturing facilities face several key safety concerns.

Fire and explosion risks are high due to ethylene’s flammability. Workers can suffocate in enclosed spaces if ethylene displaces oxygen.

Chemical exposure may cause respiratory problems and has been linked to cancer.

Plants must implement strict safety management protocols, including regular equipment inspections, worker training, and emergency response plans.

Continuous monitoring systems for leaks are essential for preventing accidents.

Who Are the Largest Global Producers of Ethylene?

The largest global ethylene producers include ExxonMobil (USA), SABIC (Saudi Arabia), Dow Chemical (USA), Shell Global (Netherlands), and Sinopec (China).

Dow Chemical leads in capacity with 13.04 million tons per year.

The USA dominates production with 17% of global share, followed by China at 15% and the GCC region at 12%.

Other major producers include INEOS, Chevron Phillips Chemical, LyondellBasell, and Reliance Industries.

What Alternative Feedstocks Can Replace Petroleum for Ethylene Production?

Alternative feedstocks for ethylene production include biomass from sugarcane and corn ethanol, which can undergo dehydration to produce ethylene.

Lignocellulosic biomass from wood and straw is also viable.

Natural gas liquids, especially ethane, have become popular due to the U.S. shale boom, offering higher yields than naphtha.

Emerging technologies include CO2 conversion pathways and novel biological routes using genetically engineered microorganisms that can directly convert CO2 to ethylene.