Wind turbines are massive structures with impressive weights. A typical 1.5 MW turbine weighs around 164 tons, equivalent to 33 adult elephants. Larger models like the 2 MW Gamesa G87 can reach 334 tons. Major components contribute differently to this weight: rotor assemblies at 36-40 tons, nacelles at 300 tons, and towers ranging from 71-220 tons. The concrete foundations alone often exceed 1,000 tons. These engineering giants present unique transportation challenges.

Giants of the energy world, wind turbines weigh much more than most people realize. A typical 1.5 MW GE wind turbine weighs about 164 tons in total, which is roughly equivalent to the weight of 33 adult elephants. Larger models like the Vestas V90 (1.8 MW) tip the scales at 267 tons, while the Gamesa G87 (2 MW) weighs in at a massive 334 tons. As turbines grow in size and power output, they generally become heavier.

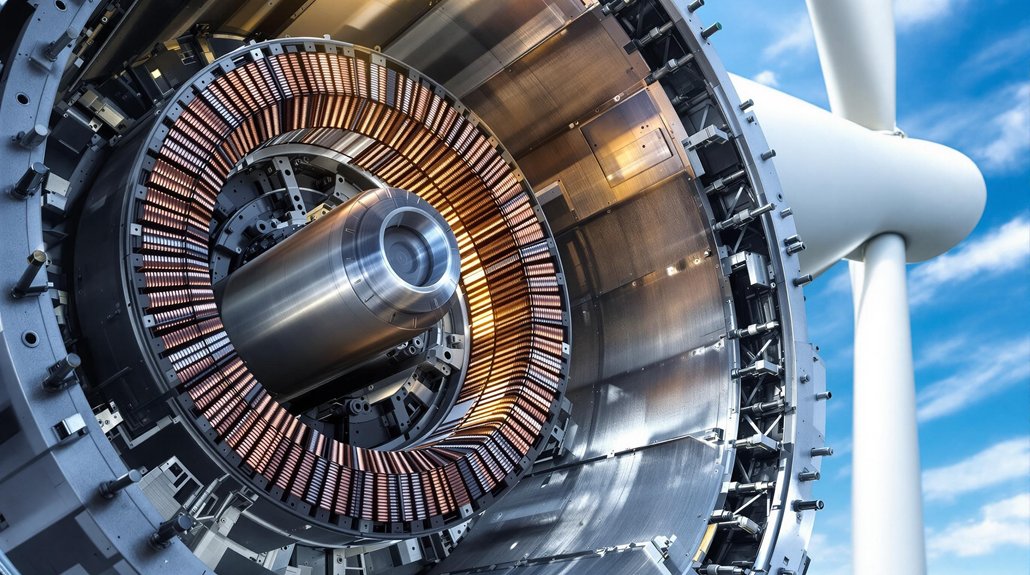

The weight of a wind turbine is distributed across several major components. The rotor assembly, which includes the blades and hub, makes up about 20% of the total cost and can weigh between 36 to 40 tons for mid-sized turbines. Individual blades weigh between 4 to 36 tons, depending on their length. They’re typically made from composite materials like fiberglass, carbon fiber, and epoxy resins. The detailed explanation of these components follows a descriptive expository approach that helps readers understand the complex structure of wind turbines.

Wind turbine blades are engineering marvels, weighing up to 36 tons each and crafted from advanced composite materials.

Towers support the entire structure and account for significant weight. The GE 1.5 MW turbine’s tower weighs about 71 tons, while larger models like the Vestas V90 and Gamesa G87 have towers weighing 152 tons and 220 tons respectively. Tower height directly impacts weight—taller towers need to be heavier to support the turbine. Despite their massive size, these structures are part of a clean energy solution that helps reduce carbon emissions worldwide.

The nacelle sits atop the tower and houses the generator, gearbox, and control systems. For a 1.5 MW turbine, the nacelle weighs approximately 300 tons. The GE 1.5 MW model has a 56-ton nacelle, while the Vestas V90’s nacelle weighs 75 tons. The GE Haliade-X, one of the largest turbines, features a rotor span 6-1/2 times larger than a Boeing 737’s wingspan.

Perhaps most surprising is the foundation weight. These concrete and steel platforms often weigh over 1,000 tons and can span 30 to 50 feet across. Offshore turbine foundations are even heavier, sometimes exceeding 2,000 tons.

These impressive weights create challenges for transportation and installation. Engineers must consider weight distribution for proper turbine balance and performance. Research continues on lighter materials that could reduce overall turbine weight while maintaining strength and durability.

Frequently Asked Questions

How Are Wind Turbines Transported to Their Installation Sites?

Wind turbines are transported to installation sites using specialized methods.

Oversized trucks with multi-axle trailers carry blades exceeding 60 meters. Railways move components over long distances. Ships and barges transport parts via water routes.

Special equipment like blade lifters and extendable trailers handle the massive pieces. Careful planning includes route surveys, escort vehicles, and off-peak scheduling to navigate infrastructure challenges and tight turns.

Do Heavier Wind Turbines Produce More Electricity?

Heavier wind turbines generally produce more electricity. Their larger rotor diameters capture more wind energy, and their taller towers access stronger winds at higher altitudes.

However, the relationship isn’t strictly proportional. Power output typically increases faster than weight as turbines scale up. Manufacturers use advanced materials to optimize the weight-to-power ratio.

Modern designs aim to maximize electricity generation while keeping weight as low as possible.

What’s the Lifespan of a Typical Wind Turbine?

Wind turbines typically last 20-25 years, with some reaching 30 years when well-maintained. Their lifespan depends on environmental conditions, component quality, and maintenance frequency.

Different parts have varying lifespans: blades (10-20 years), gearboxes (7-10 years), and generators (10-20 years). Offshore turbines often have shorter lives due to harsh conditions.

Industry financial planning generally assumes a 20-year operational lifetime for these renewable energy generators.

How Much Maintenance Do Wind Turbines Require Annually?

Wind turbines typically undergo bi-annual inspections requiring 12-18 hours of downtime each time.

Annual maintenance costs average $48,000 per turbine, about 1-2% of the original cost.

Maintenance includes cleaning blades, lubricating moving parts, checking electrical systems, and examining structural integrity.

Modern turbines use sensors for predictive maintenance, monitoring vibrations and temperatures to catch problems early.

Proper maintenance extends a turbine’s life to 20-25 years.

Can Wind Turbines Operate in Extreme Weather Conditions?

Wind turbines can operate in extreme weather conditions, but with limitations. They work in temperatures from -22°F to 104°F when equipped with special packages.

During storms, turbines automatically shut down when winds exceed 55 mph, though they’re built to withstand winds up to 156 mph.

Special adaptations exist for different environments: corrosion-resistant materials for offshore locations, sealed components for deserts, and reinforced designs for earthquake zones.