Modern wind turbines consist of five key components working together to generate electricity. The rotor blades capture wind energy and connect to the hub. Inside the nacelle, the gearbox converts slow rotation to higher speeds for the generator. A tall tower supports the entire structure. Advanced control systems monitor conditions and adjust performance. These engineering marvels transform simple wind into clean power through their carefully designed components.

Giants of renewable energy, modern wind turbines are complex machines made up of several key components working together to harness wind power. At the front of each turbine are typically three rotor blades that capture the wind’s energy. These blades are made from lightweight but strong materials like fiberglass and carbon fiber. They’re aerodynamically designed to maximize energy capture and can stretch between 30 to 80 meters long on utility-scale turbines.

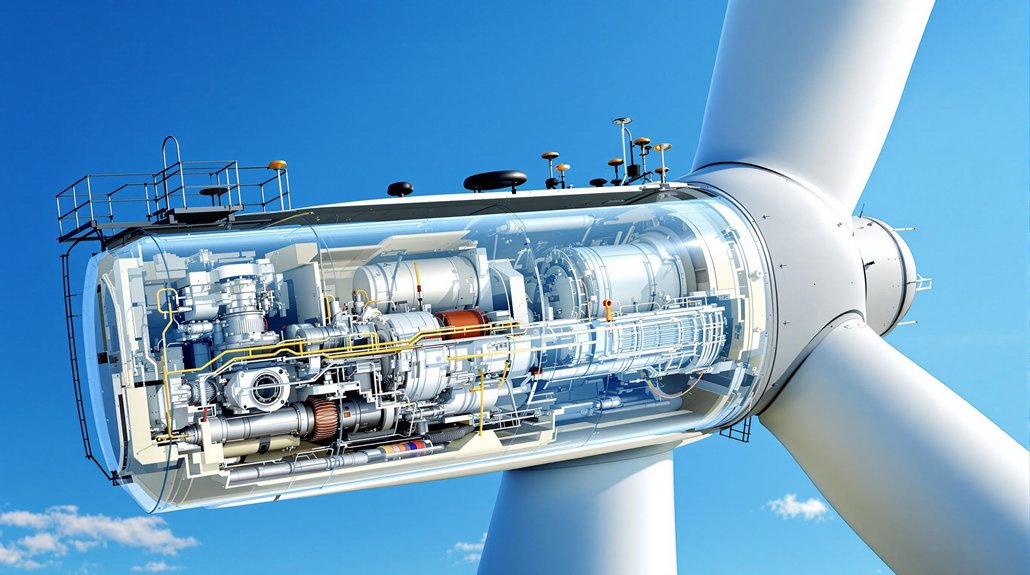

The blades connect to a hub, which is made of cast iron or steel. This hub transfers the wind’s energy to the drivetrain and houses the pitch control mechanism that adjusts blade angles. Behind the hub sits the nacelle, a housing that protects the crucial internal components from weather. The nacelle weighs between 50 and 70 tons and can rotate 360 degrees to face changing wind directions.

Inside the nacelle, the gearbox plays a critical role. It converts the slow rotation of the blades (typically 30-60 rpm) into faster speeds of 1000-1800 rpm needed by the generator. The gearbox contains complex systems of gears and bearings, making it one of the main maintenance items. Some newer turbine designs skip the gearbox entirely with “direct drive” technology.

The generator transforms the mechanical spinning energy into electricity. Most utility-scale turbines use doubly-fed induction generators with capacities ranging from 2 to 5 megawatts. These generators need cooling systems to manage heat produced during operation and output variable frequency AC power. The generator operates using induction principles established by Michael Faraday and John Henry.

Supporting everything is the tower, typically standing 80 to 120 meters tall and constructed from tubular steel sections. Towers contain ladders or lifts for maintenance access and are engineered to withstand high winds and constant vibration. These impressive structures contribute to wind energy’s land use efficiency while allowing optimal capture of wind resources.

Control systems tie everything together, monitoring wind conditions and turbine performance. They adjust blade pitch and nacelle direction, manage power output, and include safety features that shut down the turbine in dangerous wind conditions. They often allow operators to monitor and control turbines remotely.

Frequently Asked Questions

How Loud Are Wind Turbines During Operation?

Wind turbines typically create noise levels of 35-45 decibels when measured 300 meters away, similar to a refrigerator’s hum.

Directly in front of a turbine, noise can reach 60-80 decibels. The sound decreases with distance and varies with wind speed.

Turbines produce both mechanical noise from internal components and aerodynamic noise from blade movement.

Newer turbines use design improvements to reduce noise levels.

What Is the Average Lifespan of a Commercial Wind Turbine?

Commercial wind turbines typically last 20-25 years, with some reaching 30 years through proper maintenance.

Offshore turbines often have shorter lifespans due to harsh marine conditions.

While foundations and towers usually last the full lifespan, components like blades, gearboxes, and generators may need earlier replacement.

Environmental factors, material quality, and maintenance practices all affect how long these energy producers remain operational.

Can Wind Turbines Operate in Extreme Weather Conditions?

Modern wind turbines are designed to withstand extreme weather.

They’re equipped with safety systems that shut down operations when winds exceed 55 mph.

Special features include anti-icing systems for cold weather, heating elements for electrical components, and blade feathering during storms.

They’re built with weather-resistant materials and can operate in temperatures as low as -22°F.

Advanced monitoring systems help predict and respond to harsh conditions.

How Much Land Is Required for Wind Turbine Installation?

Wind turbines need about 1.5 acres for the actual structure, but 25-40 acres during construction.

The total land requirement ranges from 2-40 acres per megawatt, depending on turbine size. Turbines must be spaced 5-10 rotor diameters apart to avoid interference.

While wind farms use 30-140 acres per megawatt overall, only 2-5% of this land is directly impacted, leaving the rest available for other uses.

What Happens to Wind Turbines at the End of Their Lifecycle?

Wind turbines typically reach the end of their life after 20-25 years.

About 85-90% of components are recyclable, but blades pose challenges due to their composite materials. Most blades currently end up in landfills, with about 8,000 decommissioned annually in the US.

New methods are emerging, including grinding blades into fiberglass products, chemical recycling, and repurposing them as furniture, building materials, or public art installations.